Tsk Plastic Masterbatch Parallel Twin Screw Pelletizing/Compounding/Recycling/Granulating Extruder/Extrusion Machine

Basic Info

Model No.: TSK35B

Product Description

Model NO.: TSK35B Plastic Processed: PE,PP,PC,ABS,TPU,Tpo,Pet Feeding Mode: Multiple Feed Screw: Twin-Screw Screw Channel Structure: Deep Screw Automation: Automatic Tsk35b: Tsk65b Specification: ISO9001, CE HS Code: 84772090 Type: Pelletizing Extruder Product Type: Granulating Extruder Assembly Structure: Integral Type Extruder Engagement System: Full Intermeshing Exhaust: Exhaust Computerized: Computerized Trademark: BEIER MACHINERY Origin: China TSK Series Parallel Twin-Screw Extruder

TSK Parallel twin-screw extruder is a kind of high-efficiency compounding and extruding equipment.

The screw & barrel adopt building block type design principle to change the length of the barrel, choose different screw stem parts to assemble the line according to material characteristics to get the best work condition and max function.

Because it has good mixing, separating, dewatering and self-cleaning functions to avoid the materials wrapping the axle, caking in the extruding process. With the rotation of the screw, the surface of the materials continuously change, helps the volatile matter dewater, treat, and etc.

Machine Design

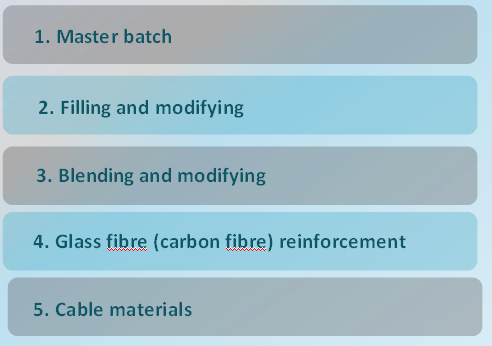

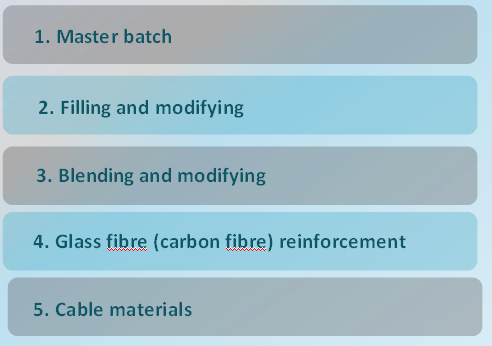

Usages of TSK Series Parallel Twin Screw Extruder

TSK35B Extruder showed in 2015 NPE Exhibition:

Technical Parameter

Contact us if you need more details on Plastic Granulating. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Compounding、Plastic Extruder. If these products fail to match your need, please contact us and we would like to provide relevant information.

TSK Parallel twin-screw extruder is a kind of high-efficiency compounding and extruding equipment.

The screw & barrel adopt building block type design principle to change the length of the barrel, choose different screw stem parts to assemble the line according to material characteristics to get the best work condition and max function.

Because it has good mixing, separating, dewatering and self-cleaning functions to avoid the materials wrapping the axle, caking in the extruding process. With the rotation of the screw, the surface of the materials continuously change, helps the volatile matter dewater, treat, and etc.

Machine Design

Usages of TSK Series Parallel Twin Screw Extruder

TSK35B Extruder showed in 2015 NPE Exhibition:

Technical Parameter

| Model | TSK-35 |

| Screw diameter (mm) | 35.6 |

| L/D | 32-52 |

| Main motor (KW) | 22 |

| Max screw speed (rpm) | 600 |

| Capacity (kg/h) | 60-90 |

Contact us if you need more details on Plastic Granulating. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Compounding、Plastic Extruder. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Extruder

Other Products

Hot Products

630mm-1200mm Plastic PE Pipe Vacuum Cooling TankPP/PE Plastic Cotton Swab Bud Stick Making MachinePPR Plastic Pipe Extrusion Extruder MachinePP PE Plastic Pipe Extrusion MachinePlastic Single Screw Extruder for Extrusion LinePE Pipe Line (GMP)Pet Recycling Line/ Pet Washing Line/ Pet Bottle Recycling Line/ Pet Recycling/ Pet Washing and Recycling Line/ Pet Flake Washing Line 500-6000kg/HPVC Suto Compounding SystemPlastic Heat/Cool Vertical Mixing UnitPC Series Strong CrusherU-PVC/M-PVC/C-PVC Pipe Extrusion LinePVC Hot-Cutting Granulation Line350kilos/h water tank guangdong plastic screw extruder plant distributor pricePE PP Film plastic washing line Compressed Squeezer Dryer DKSJ-FC10Plastic extruder and recycling machinesPE PP Film Three Stage Plastic Recycling Pelletizer Granulator Machine