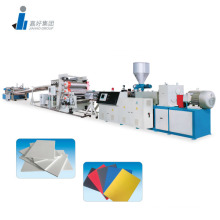

PVC Wall Panel Production Line

Basic Info

Model No.: SJSZ

Product Description

Model NO.: SJSZ Screw: Double-Screw Computerized: Computerized Customized: Customized Extruder: Twin-Screw extruder machine Cabinet Electric Parts: ABB Siemens Schneider Motor: Simens Using: PVC Ceiling Making Machine Name1: PVC Ceiling Extrusion Line Machine Transport Package: Wood Base and Wood Case Origin: Zhangjiagang City, China Product Type: PVC Profile Automation: Automatic Certification: CE, ISO9001:2008 Raw Material: PVC Inverter: ABB Gear Box: Vertical Type Voltage: 380V 50 Hz or Depends Required Name: PVC Ceiling Wall Production Line Trademark: DEEDO Specification: PVC plastic product, size depends on customer HS Code: 84778020 PVC ceiling Profile extrusion machine, PVC ceiling making machine, PVC panel extrusion machine, PVC wall panel extrusion machine

Main Model of PVC Ceiling Machine :

Components of PVC profile production line

a. Conical twin screw extruder:

Using the high efficient conical twin screws, specially designed for PVC power to ensure uniformed plasticization, high extrusion. Stable temperature controlling system can guarantee high quality Pipe extrusion.

b. Extrusion Mould:

Spiral type die head will ensure high speed extrusion and avoid the thermal decomposition of amorphous plastics and get high quality PVC profiles. There is heating control system inside of the mould, high efficient, easy to extrude. Bronze calibrators can make the PVC profiles fast calibrated and cooled.

c. Spraying and cooling table:

Rapid vacuum calibrating system allows the hot extruded PVC profiles to be cooled in a very short time and obtain the final size. Automatic temperature control system, pressure regulator, and vacuum control valve greatly enhance the sizing and cooling performance as well as the production speed.

d. Haul off machine:

Adopts caterpillar type suitable for different sizes of pipes. Haul off caterpillar blocks are made of abrasion resistant rubber material, which can make a high and stable hauling speed.

e. Cutting machine:

Precision machine cutter is able to make flat, straight cuts at high speed. A powerful suction device gathers up waste scraps after cutting, thereby making it easier for users to clean the cutter.

6. Stacking:

Automatic stacking with fixed length

if you are interested in this plastic production line,please contact me:

Mob:+86 13962461986 Contact us if you need more details on PVC Profile Extrusion Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PVC Ceiling Extruder、PVC Ceiling Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Main Model of PVC Ceiling Machine :

| Model | 51/105 | 55/110 | 55/110 | 65/132 | 65/132 |

| Applicable product width | 160mm/200mm | 250mm | 300mm | 400mm | 600mm |

| Extruder | SJSZ51/105 | SJSZ51/105 | SJSZ55/110 | SJSZ65/132 | SJSZ65/132 |

Components of PVC profile production line

a. Conical twin screw extruder:

Using the high efficient conical twin screws, specially designed for PVC power to ensure uniformed plasticization, high extrusion. Stable temperature controlling system can guarantee high quality Pipe extrusion.

b. Extrusion Mould:

Spiral type die head will ensure high speed extrusion and avoid the thermal decomposition of amorphous plastics and get high quality PVC profiles. There is heating control system inside of the mould, high efficient, easy to extrude. Bronze calibrators can make the PVC profiles fast calibrated and cooled.

c. Spraying and cooling table:

Rapid vacuum calibrating system allows the hot extruded PVC profiles to be cooled in a very short time and obtain the final size. Automatic temperature control system, pressure regulator, and vacuum control valve greatly enhance the sizing and cooling performance as well as the production speed.

d. Haul off machine:

Adopts caterpillar type suitable for different sizes of pipes. Haul off caterpillar blocks are made of abrasion resistant rubber material, which can make a high and stable hauling speed.

e. Cutting machine:

Precision machine cutter is able to make flat, straight cuts at high speed. A powerful suction device gathers up waste scraps after cutting, thereby making it easier for users to clean the cutter.

6. Stacking:

Automatic stacking with fixed length

| Payment, delivery and after sales services | ||||

| 1 | Payment terms | 30% for prepayment by T/T, 70% for balanced payment by T/T, or L/C can be acceptable | ||

| 2 | Delivery time | 60 days after receipt of prepayment | ||

| 3 | Packing method | Wooden cases/pallets with stretching films | ||

| 4 | Guaranteed time | 18 months for mechanical parts, 12 months for electrical parts | ||

| 5 | After sale service | Send 1-2 engineers to customers' factory to help them install, test the machine, and train their workers. This is chargeable | ||

if you are interested in this plastic production line,please contact me:

Mob:+86 13962461986 Contact us if you need more details on PVC Profile Extrusion Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PVC Ceiling Extruder、PVC Ceiling Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : profile extrusion line > PVC ceiling wall panel extrusion machine

Premium Related Products

Other Products

Hot Products

630mm-1200mm Plastic PE Pipe Vacuum Cooling TankPP/PE Plastic Cotton Swab Bud Stick Making MachinePPR Plastic Pipe Extrusion Extruder MachinePP PE Plastic Pipe Extrusion MachinePlastic Single Screw Extruder for Extrusion LinePE Pipe Line (GMP)Pet Recycling Line/ Pet Washing Line/ Pet Bottle Recycling Line/ Pet Recycling/ Pet Washing and Recycling Line/ Pet Flake Washing Line 500-6000kg/HPVC Suto Compounding SystemPlastic Heat/Cool Vertical Mixing UnitPC Series Strong CrusherU-PVC/M-PVC/C-PVC Pipe Extrusion LinePVC Hot-Cutting Granulation Line350kilos/h water tank guangdong plastic screw extruder plant distributor pricePE PP Film plastic washing line Compressed Squeezer Dryer DKSJ-FC10Plastic extruder and recycling machinesPE PP Film Three Stage Plastic Recycling Pelletizer Granulator Machine